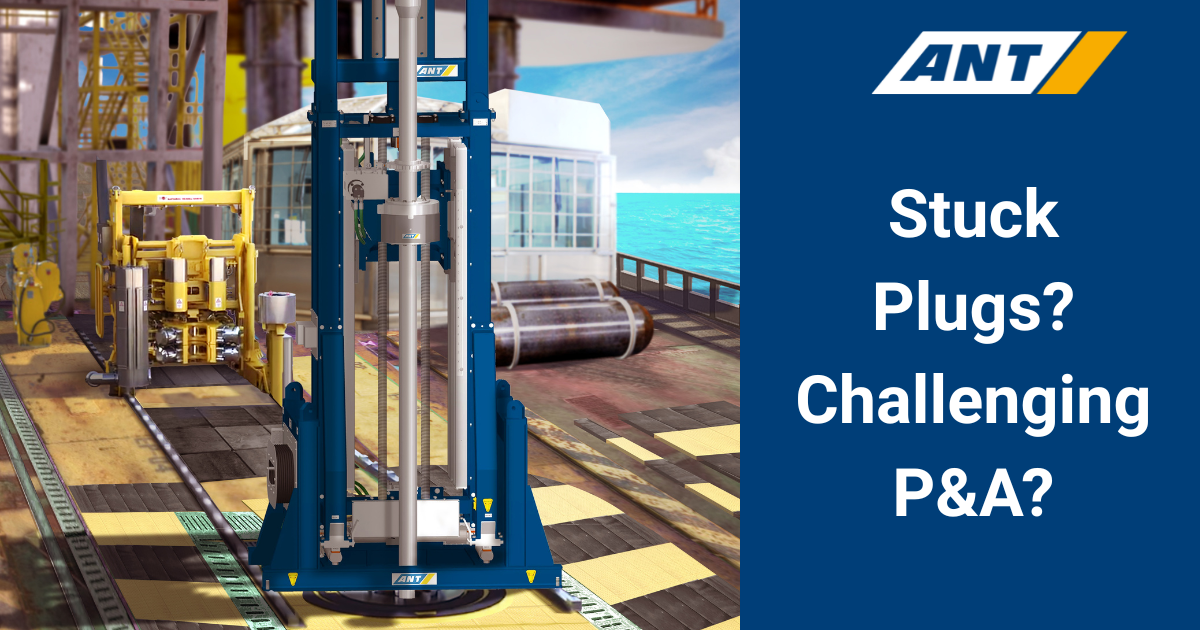

wellANT in Action: Testing the New Topside Drive System for Next-Gen Downhole Erosion

The smart rig-less solution for wellbore restrictions, plug removal, and more.

At ANT AG, we do not just develop tools — we rethink the way well intervention is done.

As global demand for efficient, cost-conscious plug & abandonment (P&A) solutions grows, our team continues to push the limits of technology with wellANT: a modular, rig-less erosion tool designed to address wellbore access challenges that conventional mechanical methods cannot solve.

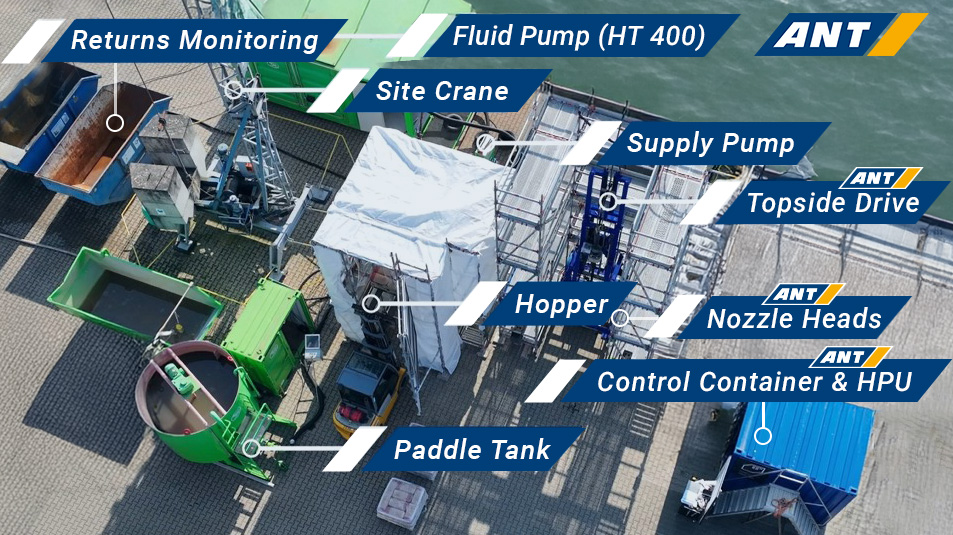

Our latest testing phase show cases a major milestone:

The integration of our brand-new Topside Drive System, which now allows precise and continuous deployment of wellANT into the wellbore — enabling smoother, deeper, and more controlled erosion processes.

What makes wellANT different?

Unlike traditional cutting or milling methods, wellANT erodes rather than cuts, ensuring minimal impact on well integrity while removing what is in the way:

- Collapsed tubulars

- Damaged plugs, packers & flapper valves (DHSV)

- Cement, organic scale, debris

- Topside gate valve erosion

- Other wellbore restrictions

This unique approach eliminates swarf, avoids heat and mechanical stress, and significantly reduces risk in sensitive environments — onshore and offshore.

Advantages of wellANT at a glance:

- Fully rig-less setup possible (future-ready via coiled tubing or drill pipe)

- Only standard topside equipment needed (water + garnet)

- Low reaction force and no weight on bit needed

- Small operational footprint

- Swarfless process = cleaner, safer wellbore

- Modular design, simple BHA, standard connections

- Cost savings and improved CO₂ balance compared to section milling.

Built for Today — Ready for Tomorrow

wellANT is already capable of handling challenging problem wells at depths up to 300 meters, offering precise erosion in situations where traditional methods fall short — such as collapsed tubulars, cement plugs, or damaged downhole safety valves (DHSV).

But that is just the beginning.

Our engineering team is currently testing and validating next-generation configurations of wellANT, aiming to unlock operational capabilities at depths up to 3,000 meters. This future-forward vision includes both rig-based deployment via drill pipe and fully rig-less applications using coiled tubing.

The goal: an all-in-one erosion-based alternative to mechanical section milling or plug-and-perf (P&P), with unmatched versatility for:

- Section eroding & side tracking

- Flapper valve and DHSV failure scenarios

- Full plug and packer removal

- Tubing cutting and cement removal

- Wellbore cleaning in complex or restricted access environments

With wellANT, operators can address a wide range of P&A and intervention challenges — with less effort, lower cost, and greater control.

📩 Want to learn more about wellANT or see it in action?

Get in touch with our team at: decom@ant-ag.com

Any questions?

Our Sales Team is always happy to help. You can reach us by phone from Monday to Friday between 8 am and 4 pm.