ERODING WITH wellANT

Stuck Plug? Collapsed Tubulars? Downhole Obstructions?

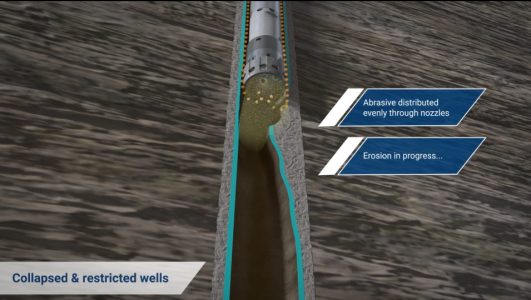

Whether during production or in the decommissioning phase – problem wells are a recurring challenge. From stuck plugs and collapsed tubulars to cement remnants and damaged valves, such obstacles lead to costly downtime and technical complications.

This is where wellANT comes in.

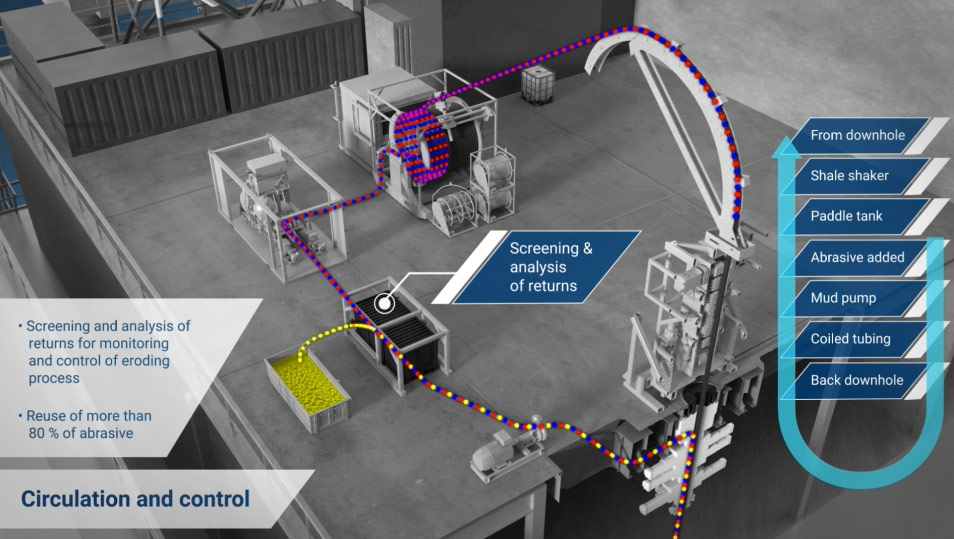

Developed by ANT AG, wellANT is a next-generation erosion tool based on our proven Water Abrasive Suspension (WAS) technology. It enables the safe and precise removal of internal wellbore obstructions without mechanical force, heat, or swarf – preserving well integrity at all times.

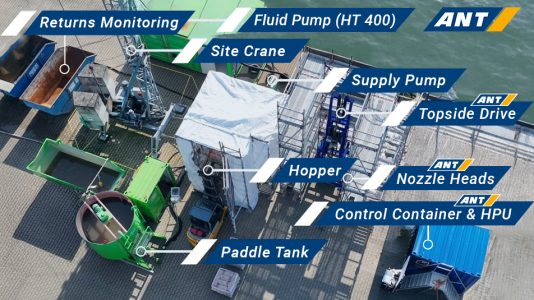

Currently, wellANT is in advanced field testing and operates in shallow water depths via our Topside Drive System (TSDS) on various jointed pipe configurations. The design is modular, robust, and engineered to meet the evolving demands of plug & abandonment (P&A) and intervention.

wellANT Current Status (2025)

- Ready for Deployment

- Shallow water applications

- Modular, Versatile, Light weight

Future Vision: smart wellANT

The long-term vision of wellANT includes a fully rigless, smart downhole solution, operable via Coiled Tubing (CT).

Future tool concept includes:

-

Smart communication and power lines

-

Stroker Unit (1–6 mm/min penetration)

-

Rotation Unit (3–12 rpm)

-

Advanced multi-nozzle erosion head

Planned capabilities:

-

Operation in deep and ultra deep waterdepths

-

Section eroding

-

Side tracking

-

PWC alternative

-

All current P&A functionalities extended to deeper wells

Why wellANT? – Key Advantages

- Smart design – modular, compact, and easy to integrate

- Standard topside equipment only – mud fluid & garnet

- Swarfless – no mechanical debris, no cleanup

- Minimal footprint – ideal for limited deck space

- Low reaction forces – safe and stable operation

- Good CO₂ balance – environmentally conscious

- Cost-effective – fewer tools, fewer intervention steps

- Erodes any material – preserves well integrity

Any questions?

Our Sales Team is always happy to help. You can reach us by phone from Monday to Friday between 8 am and 4 pm.

Blog

ANT in March 2026: Subsea Intervention & P&A in Rio & Perth

Two key events, two technical talks: Subsea Intervention & Well Integrity (SPE Rio) and Decommissioning/P&A (EXA Perth). Meet ANT on site.

Meet our ANT EOD experts – two opportunities for a good conversation about explosive ordnance disposal

Visit ANT at ENFORCE TAC 2026 (February 23–25, Nuremberg) or meet us in Bad Kissingen. Live demo: MACE compatible with the ROV tEODor (Telerob). WAS cold cutting for EOD/IEDD.

ANT AG joins EMDAD at ADIPEC 2025

EMDAD as exhibitor at ADIPEC 2025—and ANT AG will join as a co-exhibitor. At our booth, ANT AG will focus on wellANT: the next-generation erosion tool based on Water Abrasive Suspension (WAS) technology.