Shaping the future together

Internal cutting

of multi-string casings and piles

Fields of application

- Multi-string casings

- Casings and single piles

- Water depth up to 250 m

Special Features

- Most powerful & precise jet at 36.000 psi

- Optional dewatering module

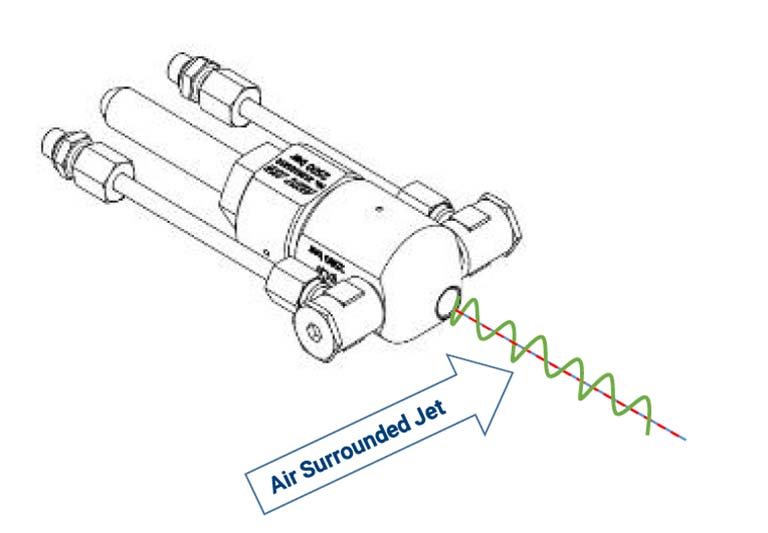

- Air surrounded jet

- High cut quality: with or without cement

- Verified and proven water depth = 150 m, with dewatering module 250 m

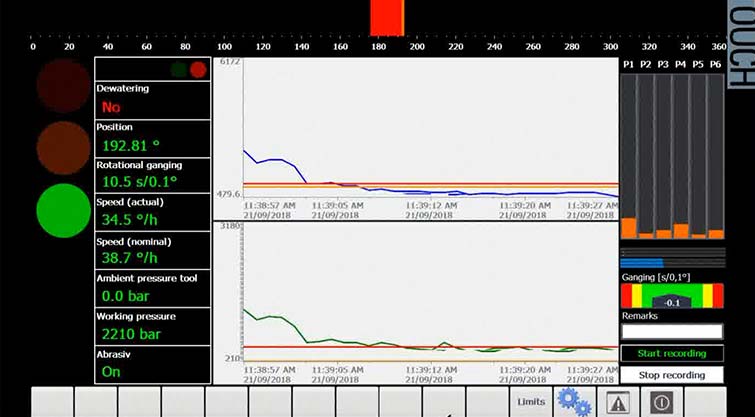

- 3S cut verification system real time cut verification

What makes WAS cutting tools of ANT so specific?

Besides the general advantages of the Water Abrasive Suspension (WAS) cutting technology, ANT has developed specific solutions to further improve performance of the Downhole Cutting Heads (DCHs) in great depth and challenging conditions of internal cuts. Even concentric multistring dual bore wells can be completely cut in a single pass.

Cutting examples

Offshore job in the gulf of Mexico

ID 7 5/8″ OD 36″ / Water depth 60′ / 20m

average casing setup, cemented

average cutting speed 30° / h, cutting time 12h

Offshore job in the

Chinese Sea / Bohai Bay

ID 13 3/8″ OD 30″ / Water depth 60′ / 20m

average casing setup, cemented

average cutting speed 80° / h, cutting time 4,5h

Mock-up test

ID 13 3/8″ OD 30″ / Water depth 15′ / 4m

average casing setup, cemented

average cutting speed 100° / h, cutting time 3,5h

“ANTs products and service is excellent. Using their tools for our Offshore projects is lucrative and practicable.”

Wang Chao – CNOOC

Turnkey offshore WAS cutting spread

High Pressure Pump*

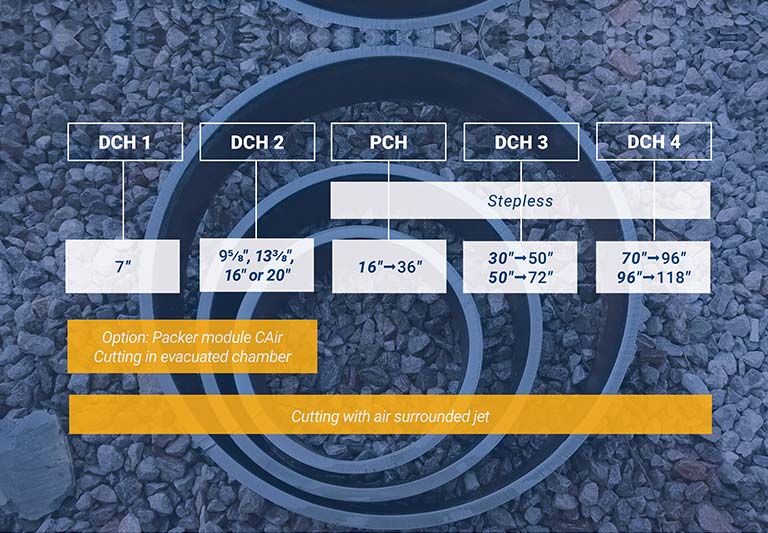

- Various types of Downhole Cutting Head (DCHs) and Pile Cutting Head (mounted on skid), some with optional packer module CAir.

- A-frame with goose neck*

- Winch* and Umbilical

- Air compressor*

- Abrasive Mixing Units (AMUs) with Lifting Unit and external Switch Box

- Control System and Hydraulic Power Unit

- High Pressure Pump*

- Working Container*

- Abrasive Container*

- External tugger wire e.g. lifting device**

Overview of ANT’s Water Abrasive Suspension (WAS) cutting spread

**provided by customer

**provided by customer

Key Features

- Turnkey WAS cutting spread

- Small footprint

- Modular tools

- Smart monitoring system

- High quality materials

- Reliable and proven technology

Your Advantages

- Control and feedback

- High flexibility

- Time savings

- Cost reduction

- Maximum safety

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCore components of

the WAS Cutting Spread

Abrasive Mixing Units (AMUs)

Our standard WAS offshore spread comes with an ATEX Zone 2 certified complete AMU TWIN 2500-100 system which ensures safe operation and transport as well as interruption-free cutting.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCutting Devices: Downhole Cutting Heads (DCHs) and Pile Cutting Head (PCH)

3S Cut Verification System

Offshore subsea cutting implies being “blind”, especially during internal cuts of multistring casings. Our 3S cut verification system makes the whole cutting process visible in real time. A variety of sensors are used to display the cut in real time on a monitor, giving the operator reliable feedback and full control during the entire cutting process.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationUmbilical

Any questions?

Our Sales Team is always happy to help. You can reach us by phone from Monday to Friday between 8 am and 4 pm.

Blog

ANT in March 2026: Subsea Intervention & P&A in Rio & Perth

Two key events, two technical talks: Subsea Intervention & Well Integrity (SPE Rio) and Decommissioning/P&A (EXA Perth). Meet ANT on site.

Meet our ANT EOD experts – two opportunities for a good conversation about explosive ordnance disposal

Visit ANT at ENFORCE TAC 2026 (February 23–25, Nuremberg) or meet us in Bad Kissingen. Live demo: MACE compatible with the ROV tEODor (Telerob). WAS cold cutting for EOD/IEDD.

ANT AG joins EMDAD at ADIPEC 2025

EMDAD as exhibitor at ADIPEC 2025—and ANT AG will join as a co-exhibitor. At our booth, ANT AG will focus on wellANT: the next-generation erosion tool based on Water Abrasive Suspension (WAS) technology.