Cut safely and efficiently

WAS cutting technology

Water Abrasive Suspension (WAS) cutting process

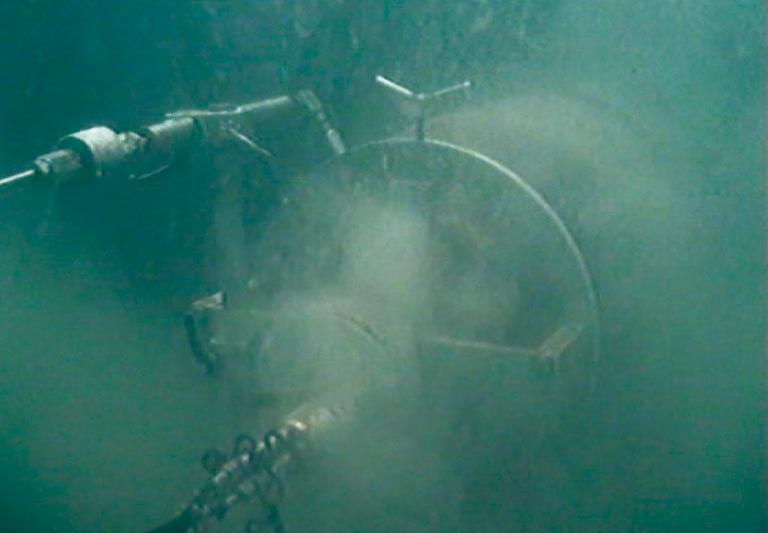

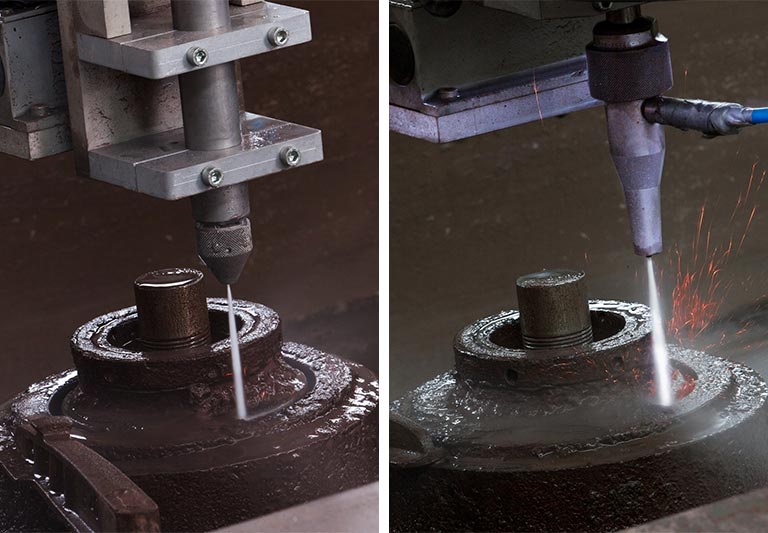

With the Water Abrasive Suspension (WAS) cutting process, almost all materials can be cut with the aid of a cold high pressure water jet and sharp-edged abrasive. The cuts are executed in a contact-free manner, with no heat generation or deformation. This specialised technology is used both in air and under water. Depending on the area of application, it enables the remote-controlled cutting of materials of up to 1,000 mm thickness from up to 1,000 m away.

How does the Water Abrasive Suspension (WAS) cutting process work?

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationFields of application

- Dismantling and maintenance of offshore installations above and under water

- Disarming of unexploded ordnance (EOD) and improvised explosive devices (IEDD)

- Dismantling and maintenance of a wide variety of installations in sensitive, explosive or radioactive areas

- Industrial manufacturing

- Challenging cuts in extraordinary situations

Key Features

- Cuts almost any material

- Cutting in air and under water

- Cold cutting process

- Contactless cut

- No sparking

- Suitable for ATEX-zones and cutting explosives

- High cutting performance even with very thick materials

- High cutting quality, post processing not required

- Remote operation from a large distance

- Low particle emission

- Low noise emission

- Energy efficient

The WAS cutting process in brief

The Water Abrasive Suspension (WAS) is fed to the cutting nozzle via a high-pressure hose and pressed through it. The potential energy represented by the pressure and the flow is converted into a cutting jet with a velocity of several hundred meters per second.

The result is a two-phase cutting jet consisting of approximately 97.5 vol. percent water and 2.5 vol. percent abrasive. Since the abrasive particles in WAS systems are bound directly in the water, the suspension jet is much more stable, precise and powerful than the injection jet.

Components of a WAS cutting system

The core components of a Water Abrasive Suspension (WAS) cutting system are a high pressure pump, an abrasive mixing unit (AMU) and a nozzle.

Depending on the application, specialised remote-controlled cutting devices, monitoring and control systems as well as other accessories are deployed

Do you have any questions?

Our project team will be happy to help. You can reach us by phone Monday to Friday from 8am to 4.30pm

Blog

ANT in March 2026: Subsea Intervention & P&A in Rio & Perth

Two key events, two technical talks: Subsea Intervention & Well Integrity (SPE Rio) and Decommissioning/P&A (EXA Perth). Meet ANT on site.

Meet our ANT EOD experts – two opportunities for a good conversation about explosive ordnance disposal

Visit ANT at ENFORCE TAC 2026 (February 23–25, Nuremberg) or meet us in Bad Kissingen. Live demo: MACE compatible with the ROV tEODor (Telerob). WAS cold cutting for EOD/IEDD.

ANT AG joins EMDAD at ADIPEC 2025

EMDAD as exhibitor at ADIPEC 2025—and ANT AG will join as a co-exhibitor. At our booth, ANT AG will focus on wellANT: the next-generation erosion tool based on Water Abrasive Suspension (WAS) technology.