EOD and Demilitarization

Disarming unexploded ordnance for civil and military security tasks

The environmental conditions that unexploded ordnance is exposed to over time have chemical as well as physical effects and often result in a critical unexploded ordnance (UXO) situation on site. Conventional Render Safe Procedures (RSP) are often not feasible without touching or moving the unexploded ordnance. Blasting unexploded ordnance has been the last RSP to be used and sometimes causes high collateral damage. Additionally, underwater blasting leaves severe environmental damage by damaging or killing marine life. That’s where ANT AG presents its waterjet cutting technology as an EOD solution in order to cut UXO in the safest way possible.

MACE: The EOD solution

MACE systems are successfully deployed around the globe and have become the state of the art for RSP: For the safe, remote disposal of all types of explosive devices, ANT offers customised solutions to cut UXO with sophisticated components.

Fields of application

- Fuses which cannot be manually removed or deactivated

- Ammunition with chemically dangerous mutated explosive content

- Opening of containments or objects, without using explosives as opening method for deflagration

Key Features

- Suitable for EOD and Demilitarization

- 700 bar

- Portable

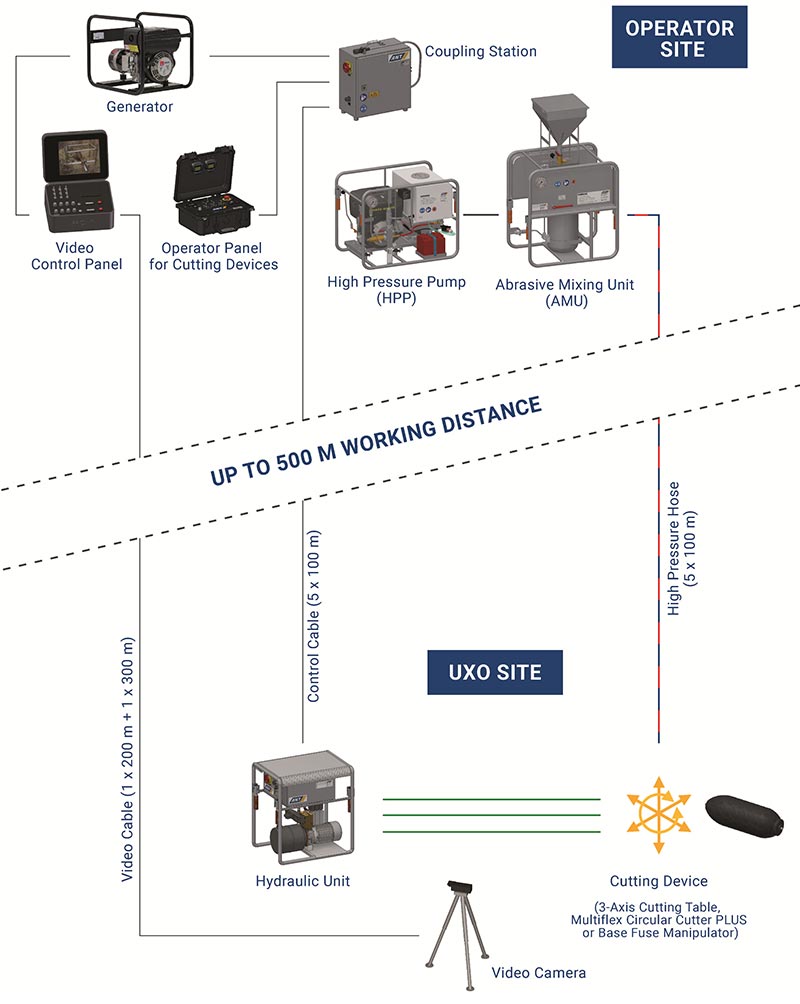

- Up to 500 m distance from UXO

- Cutting time approx. 20 min with one filling of abrasive

- Also available as XL version (cutting time approx. 45 min with one filling of abrasive)

System configuration

EOD solutions: MACE system

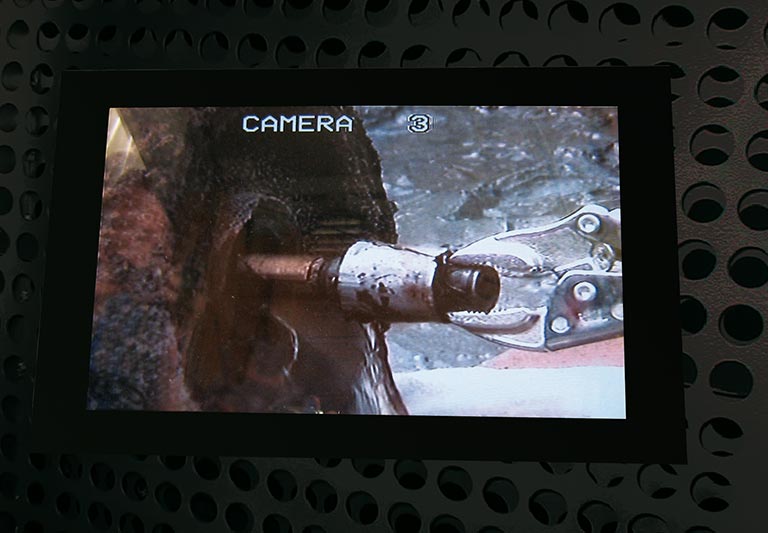

MACE Cutting Examples for EOD

Cutting out a bottom plate

References EOD/IEDD

MACE & Components

ANT provides a hydraulic power unit with an intuitive operator panel which ensures effective control of the cutting devices.

Do you have any questions?

Our sales team will be happy to help. You can reach us by phone Monday to Friday from 8 am to 4 pm.

Blog

ANT in March 2026: Subsea Intervention & P&A in Rio & Perth

Two key events, two technical talks: Subsea Intervention & Well Integrity (SPE Rio) and Decommissioning/P&A (EXA Perth). Meet ANT on site.

Meet our ANT EOD experts – two opportunities for a good conversation about explosive ordnance disposal

Visit ANT at ENFORCE TAC 2026 (February 23–25, Nuremberg) or meet us in Bad Kissingen. Live demo: MACE compatible with the ROV tEODor (Telerob). WAS cold cutting for EOD/IEDD.

ANT AG joins EMDAD at ADIPEC 2025

EMDAD as exhibitor at ADIPEC 2025—and ANT AG will join as a co-exhibitor. At our booth, ANT AG will focus on wellANT: the next-generation erosion tool based on Water Abrasive Suspension (WAS) technology.