Safety for future

IEDD

Improvised Explosive Device Disposal

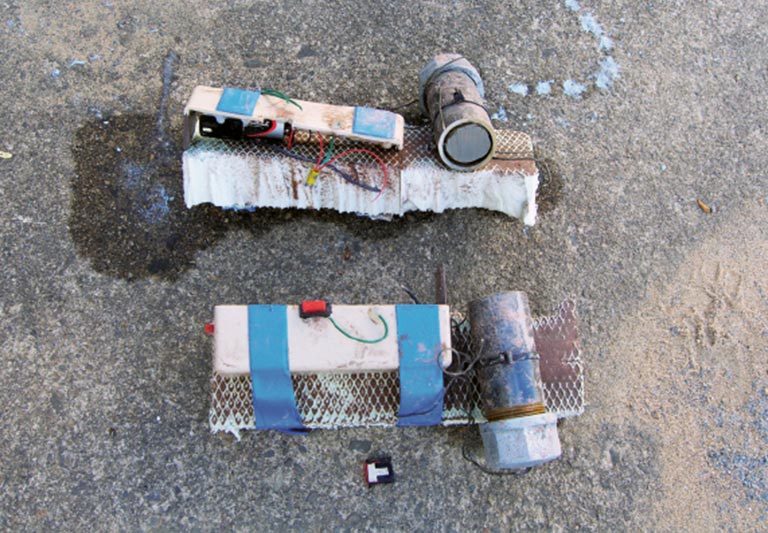

Pipe bombs, hand grenades, or potentially dangerous objects such as unconventional explosive devices in the form of fire extinguishers, gas cylinders and suitcases, as well as vehicles are often used in terrorist attacks. The use of a water gun as a defusing procedure (RSP – Render Safe Procedure) often causes severe collateral damage, especially in urban areas. ANT AG has therefore developed self-sufficient complete systems for the safe disposal of improvised explosive devices (IEDD – Improvised Explosive Device Disposal) using the waterjet cutting method.

Fields of application

- Pipe bombs

- Hand grenades

- Unconventional explosives like gas bottles, suitcases or fire extinguishers

- Large Vehicle Bombs (LVB)

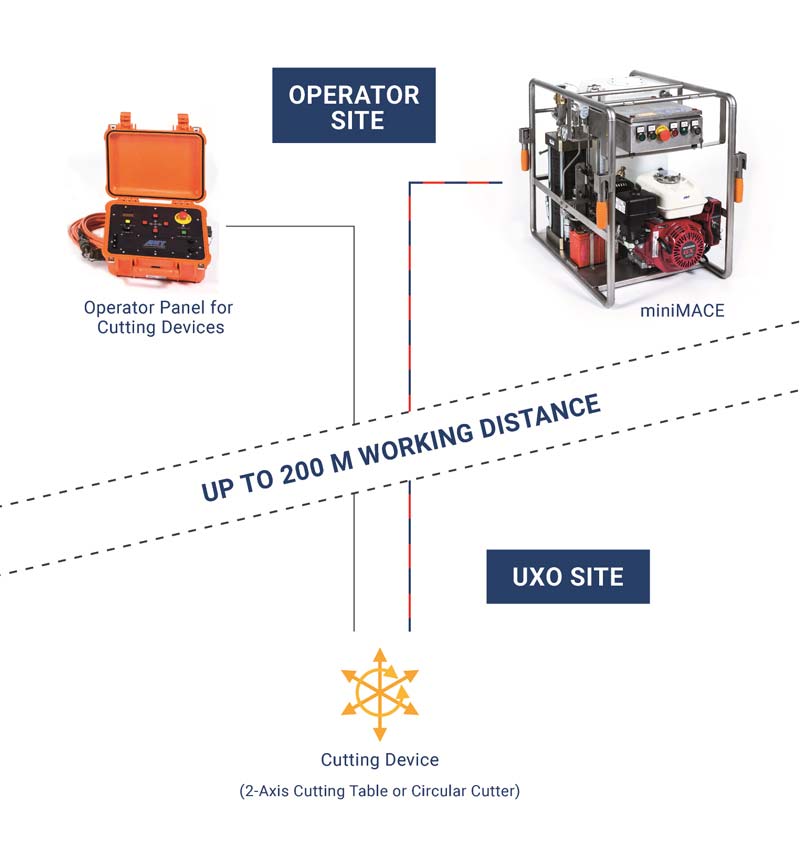

The miniMACE Solution

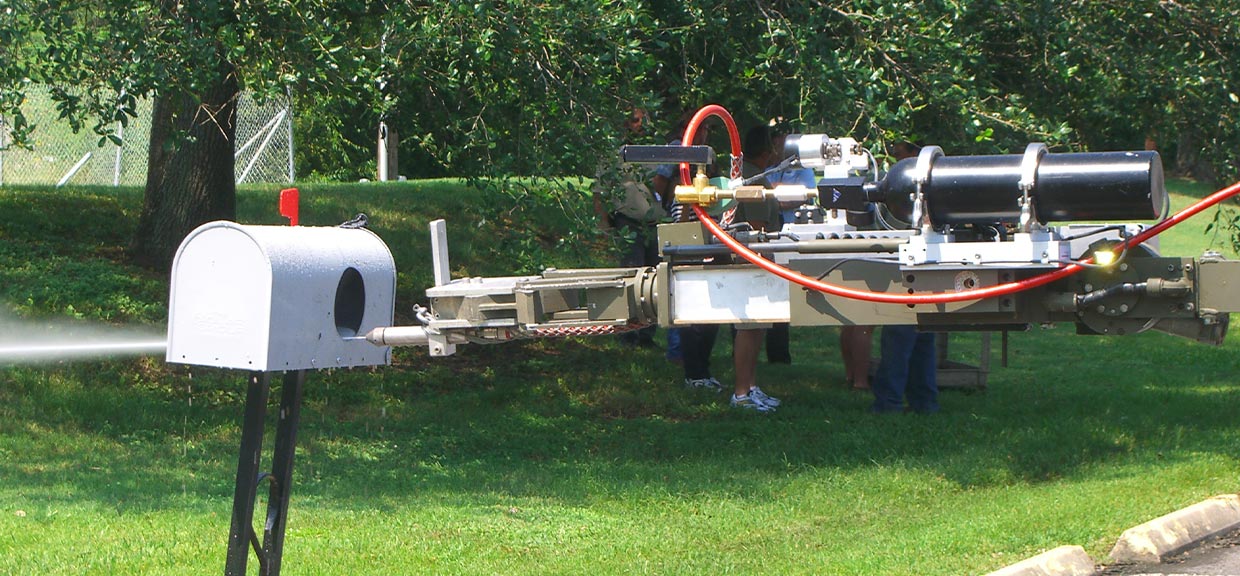

miniMACE is a self-contained complete system with combustion engine, abrasive mixing unit (AMU) and high pressure pump (HPP) for accessing and deactivating Improvised Explosive Devices (IED). It can be used for car bombs (LVB – Large Vehicle Bombs) or other containers in which IEDs have been hidden, regardless of the material of the body such as steel, aluminium, plastic, wood, fibreglass, glass, etc. The miniMACE system can be connected to selected EOD robots.

miniMACE key features

- Suitable for IEDD

- 450 bar

- Portable

- Applicable with optional cutting devices or with ROV

- No destruction but preservation of forensic evidence

- Up to 200 m distance from IED

The miniMACE LVB Features

- Safe and reliable access to the inside

- No destruction but preservation of forensic evidence

- Optimal risk assessment

- Ability to carry out the Render Safe Procedures (RSP) inside

Cutting IEDs with miniMACE

Cutting Large Vehicle Bombs (LVB) with miniMACE on ROV

miniMACE & Components

Do you have any questions?

Our sales team will be happy to help. You can reach us by phone Monday to Friday from 8 am to 4 pm.

Blog

ANT in March 2026: Subsea Intervention & P&A in Rio & Perth

Two key events, two technical talks: Subsea Intervention & Well Integrity (SPE Rio) and Decommissioning/P&A (EXA Perth). Meet ANT on site.

Meet our ANT EOD experts – two opportunities for a good conversation about explosive ordnance disposal

Visit ANT at ENFORCE TAC 2026 (February 23–25, Nuremberg) or meet us in Bad Kissingen. Live demo: MACE compatible with the ROV tEODor (Telerob). WAS cold cutting for EOD/IEDD.

ANT AG joins EMDAD at ADIPEC 2025

EMDAD as exhibitor at ADIPEC 2025—and ANT AG will join as a co-exhibitor. At our booth, ANT AG will focus on wellANT: the next-generation erosion tool based on Water Abrasive Suspension (WAS) technology.