Railway Track Maintenance and Cleaning

Ensuring Optimal Performance

Overview

Important questions

- Preventive Maintenance: Regular inspections and maintenance activities to prevent potential issues.

- Corrective Maintenance: Addressing specific issues identified during inspections or continuous monitoring.

- Predictive Maintenance: Using data analysis and condition monitoring to predict maintenance needs and optimize schedules.

- Emergency Maintenance: Immediate repairs in response to unforeseen failures or safety concerns.

- Safety: Preventing accidents and ensuring reliable operations.

- Operational Efficiency: Minimizing disruptions and optimizing train schedules.

- Cost Management: Reducing long-term repair costs through proactive problem-solving.

- Rail Grinding Machines: Smoothing out unevenness and extending the life of rails.

- Tamping Machines: Ensuring proper alignment and stability of tracks.

- Welding Equipment: Repairing and connecting rail sections.

- Track Inspection Devices: Including ultrasound testers and thermal imaging cameras for defect detection.

Water Jet Technology: The Revolution in Rail Cleaning for Safer Railway Traffic

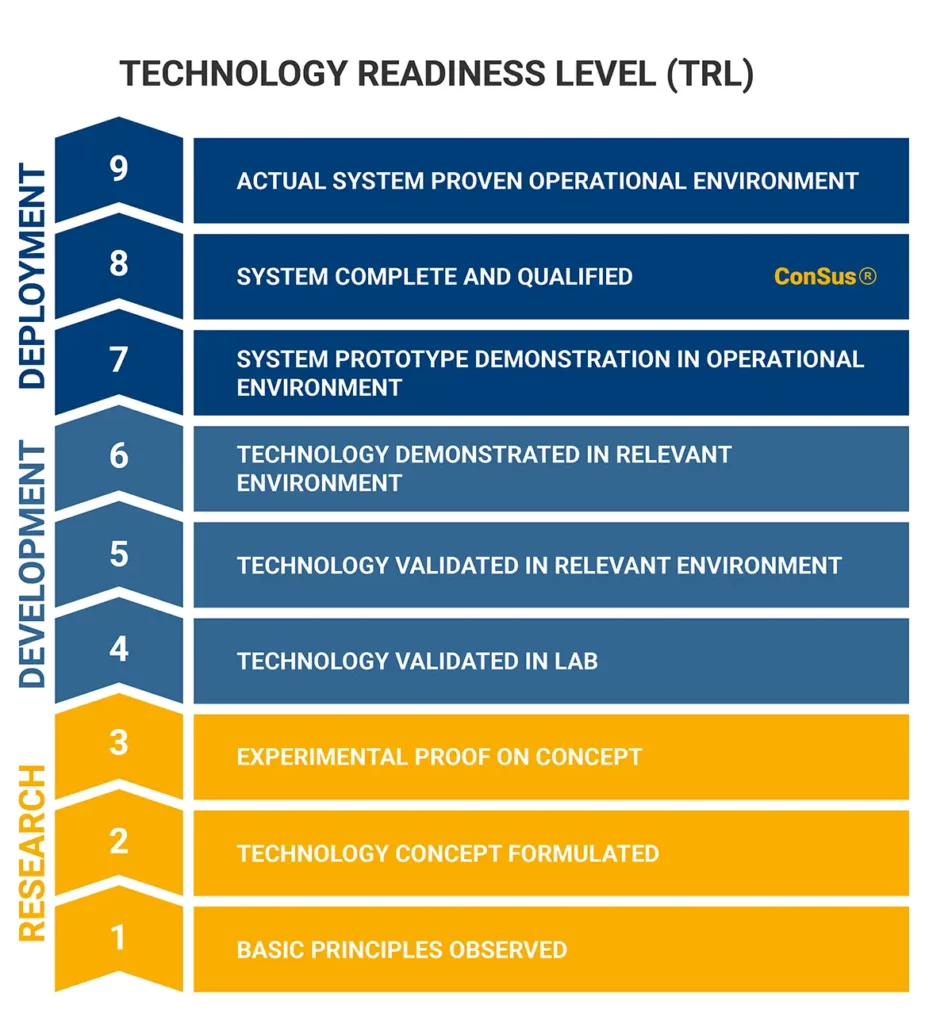

ConSus® Water Jet Cleaning Technology

Before / After

Comparison of Laser and Waterjet Technologies in Rail Cleaning

- Highest Effectiveness: Water jet technology offers the best performance in increasing the friction coefficient and reducing contamination. It can effectively remove all types of contaminants.

- Versatility: Unlike laser technology, which is less effective on oily contaminants, water jet technology can handle a wide range of contaminants, including heavy oils and organic materials, effectively.

- Safety: The risks associated with high-pressure water are lower compared to the potential hazards of laser beams. There is no risk of eye damage or skin burns, making handling safer.

- Proven Technology: Water jet technology is well-established and widely used. The necessary equipment and procedures for maintenance and operation are mature and reliable.

- Simple Safety Measures: While laser usage requires stringent safety precautions, the safety measures for water jet technology are easier to implement and do not require highly specialized protective measures. Measures like protective clothing and barriers are generally sufficient.

- Extensive Experience: Since water jet technology has been in use for a long time, there is extensive experience and knowledge about its optimal application and maintenance, further increasing efficiency and reliability.

- Operation: Water Jet Technology scored higher due to its simplicity and well-established operation procedures.

- Effectiveness: Water Jet Technology is significantly more effective in increasing friction coefficient and reducing contamination.

- Maintenance: Both technologies require regular maintenance, but Water Jet Technology has a slight edge due to its maturity and established procedures.

- Safety: Water Jet Technology is safer, with simpler safety measures compared to the stringent requirements for Laser Technology.

- Logistics: Both technologies have logistical challenges

Comparison of Laser and Water Jet Technologies in Rail Cleaning

Laser Technology:

- Operation: Pulsed Laser Ablation uses infrared lasers to vaporize contaminants and turn them into dust. A plasma plume is generated, which ablates the contamination.

- Effectiveness: Laser technology offers moderate effectiveness. It shows good results on natural contaminants but is less efficient on oily contaminants.

- Maintenance: Requires regular inspections and calibrations. Maintenance can be performed both on-site and in depots, but specialized equipment and expertise are needed.

- Safety: Class 4 lasers require extensive safety measures to prevent eye damage and skin burns.

- Logistics: The modular design allows flexible installations, but the technology is still in the optimization phase to achieve higher efficiency and lower energy consumption.

Water Jet Technology:

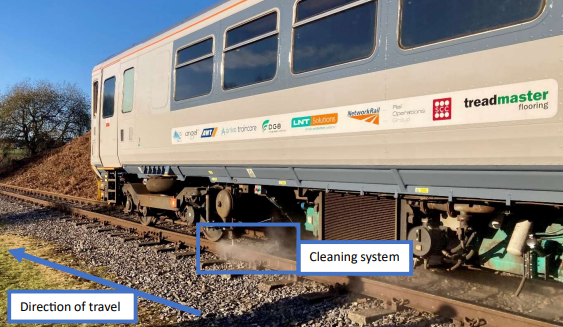

- Operation: High-pressure water jet (300-750 bar) that removes contaminants from the rail head at speeds of up to 96 km/h. The water jet cleans the rail head and ensures a direct contact surface between the wheel and the rail.

- Effectiveness: Water jet technology is the most effective in increasing the friction coefficient and reducing contamination. It works effectively on all types of contaminants, including oil, leaves, and general rail contaminants.

- Maintenance: Regular inspections and maintenance are necessary, but they are well-established and can be efficiently performed.

- Safety: Water consumption is low compared to traditional water jet cleaning methods, approximately one-tenth of the usual amount. The ConSus® technology is mature and can be operated with existing machines and infrastructure.

Case Study: Effectiveness of ConSus® Technology

Learn more about our successful application of ConSus water jet cleaning technology in a detailed case study. This study includes the simulation of leaf deposits on rails, friction measurement with the Rivelin Rail tribometer, and quantitative results after applying our cleaning system. Visit our Case Studies page to learn more.

Do you have any questions?

Blog

ANT in March 2026: Subsea Intervention & P&A in Rio & Perth

Two key events, two technical talks: Subsea Intervention & Well Integrity (SPE Rio) and Decommissioning/P&A (EXA Perth). Meet ANT on site.

Meet our ANT EOD experts – two opportunities for a good conversation about explosive ordnance disposal

Visit ANT at ENFORCE TAC 2026 (February 23–25, Nuremberg) or meet us in Bad Kissingen. Live demo: MACE compatible with the ROV tEODor (Telerob). WAS cold cutting for EOD/IEDD.

ANT AG joins EMDAD at ADIPEC 2025

EMDAD as exhibitor at ADIPEC 2025—and ANT AG will join as a co-exhibitor. At our booth, ANT AG will focus on wellANT: the next-generation erosion tool based on Water Abrasive Suspension (WAS) technology.