THE MOST EFFICIENT WAY OF WATERJET CUTTING

Rigless Plug & Abandonment

Collapsed and restricted wells, side tracking, section eroding

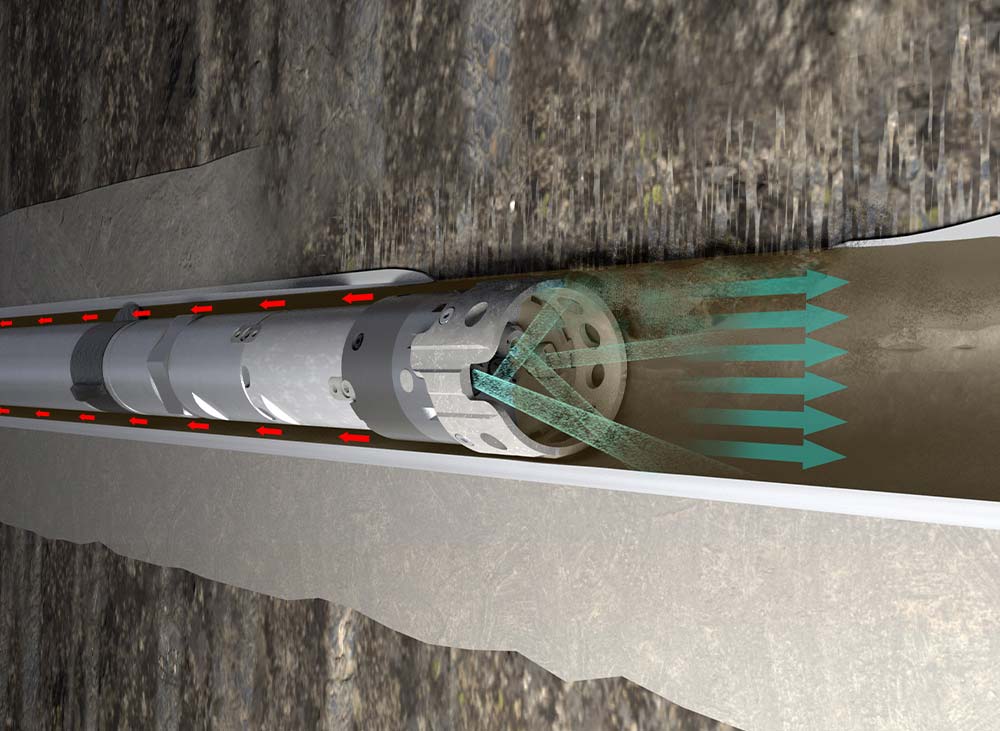

The wellANT is an exciting erosion tool that ensures high efficiency in rigless P&A and production enhancement. The tool has been engineered from ANT AG’s decades of experience in downhole solutions, and comprises:

- Drive unit

- Stroker module

- Rotation module, and

- Nozzle head

Where is wellANT used?

- Erosion of restrictions and collapsed wells

- Swarfless sectional eroding for abandonment plugs

- Erosion for side tracking

What advantages does wellANT offer?

How does wellANT work?

First of all, the wellANT is deployed downhole on coiled tubing (adaption for drill pipe possible). As the tool activates erosion by abrasive water jet, continual flow carries micro cuttings and mud to the surface, where they are screened and analysed, providing insight into what is going on downhole. A customised jet orientation has been refined to ensure the wellANT only erodes within the diameter of the existing wellbore, with very low reactive torque. wellANT can also be used to complement traditional drilling assemblies in side-tracking. Utilising the consistency of water jet cutting, the tool can be deflected via cement plug, whipstock or open hole whipstock, to provide a clear pilot hole through multiple materials.

Why wellANT is the perfect solution?

Whether working alone, or alongside traditional drilling assemblies, wellANT’s capability brings advantages in cost, time, and the quality of the end result. The versatility of wellANT means it can bring advantages throughout the well lifecycle, from production enhancement all the way through to plug and abandonment scopes.

wellANT keyfacts

- 1. What is wellANT:

The wellANT is an exciting erosion tool that ensures high efficiency in rigless P&A and production enhancement - 2. Components:

Comprises Stroker module, Drive unit, Rotation module, and Nozzle head - 3. Advantages of use:

Whether working alone, or alongside traditional drilling assemblies, wellANT’s capability brings advantages in cost, time, and the quality of the end result.

Sie sehen gerade einen Platzhalterinhalt von YouTube. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenAny questions?

Our Sales Team is always happy to help. You can reach us by phone from Monday to Friday between 8 am and 4 pm.

Blog

Sales Manager – Interview mit Peschu Kohly

Peschu Kohly ist seit dem 1. Oktober 2025 Sales Manager für den EOD-Bereich sowie im Business Development für den Bereich der Schienenreinigung. Wir haben mit ihm über seine ersten Eindrücke, seine Motivation und seine Pläne für die Zukunft gesprochen.

ANT AG joins EMDAD at ADIPEC 2025

EMDAD as exhibitor at ADIPEC 2025—and ANT AG will join as a co-exhibitor. At our booth, ANT AG will focus on wellANT: the next-generation erosion tool based on Water Abrasive Suspension (WAS) technology.

Meet the ANT EOD Team – drei Gelegenheiten für ein gutes Gespräch

NATO EOD Bratislava (Booth 305), Milipol Paris (Halle 5A, M160 – Co-Exhibitor SCOPEX) und MILENG COE Ingolstadt (Stand 82). Jetzt Gesprächstermin sichern: mace@ant-ag.com