THE MOST EFFICIENT WAY OF WATERJET CUTTING

Technology

What is wellANT?

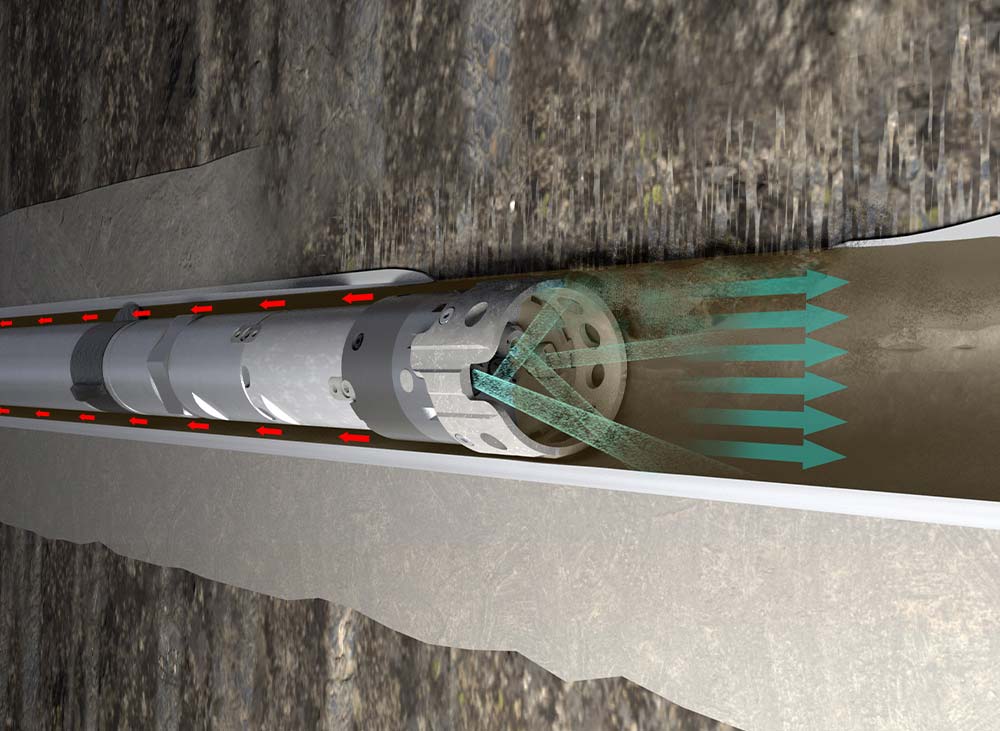

The wellANT is an exciting erosion tool that ensures high efficiency in rigless P&A as well as production enhancement. ANT AG’s decades of experience in downhole solutions enabled the development of the tool, which comprises:

- Drive unit

- Stroker module

- Rotation module, and

- Nozzle head

Where is wellANT used?

The device is flexible and can be used from Ship, Vessel or Drill Rig as well as:

- Erosion of restrictions and collapsed wells

- Swarfless sectional eroding for abandonment plugs

- Erosion for side tracking

What advantages does wellANT offer?

How does wellANT work?

Why is wellANT the perfect solution?

Whether working alone or alongside traditional drilling assemblies, wellANT brings advantages in cost, time, and the quality of the end result. The versatility of wellANT means it can bring advantages throughout the whole well lifecycle, from production enhancement all the way through to plug and abandonment scopes.

wellANT keyfacts

- 1. What is wellANT:

The wellANT is an exciting erosion tool that ensures high efficiency in rigless P&A and production enhancement - 2. Components:

Comprises Stroker module, Drive unit, Rotation module, and Nozzle head - 3. Advantages of use:

Whether working alone, or alongside traditional drilling assemblies, wellANT’s capability brings advantages in cost, time, and the quality of the end result.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationAny questions?

Our Sales Team is always happy to help. You can reach us by phone from Monday to Friday between 8 am and 4 pm.

Blog

ANT in March 2026: Subsea Intervention & P&A in Rio & Perth

Two key events, two technical talks: Subsea Intervention & Well Integrity (SPE Rio) and Decommissioning/P&A (EXA Perth). Meet ANT on site.

Meet our ANT EOD experts – two opportunities for a good conversation about explosive ordnance disposal

Visit ANT at ENFORCE TAC 2026 (February 23–25, Nuremberg) or meet us in Bad Kissingen. Live demo: MACE compatible with the ROV tEODor (Telerob). WAS cold cutting for EOD/IEDD.

ANT AG joins EMDAD at ADIPEC 2025

EMDAD as exhibitor at ADIPEC 2025—and ANT AG will join as a co-exhibitor. At our booth, ANT AG will focus on wellANT: the next-generation erosion tool based on Water Abrasive Suspension (WAS) technology.