Shaping the future together

ERODING WITH wellANT

Erosion tools for rigless P&A and production enhancement

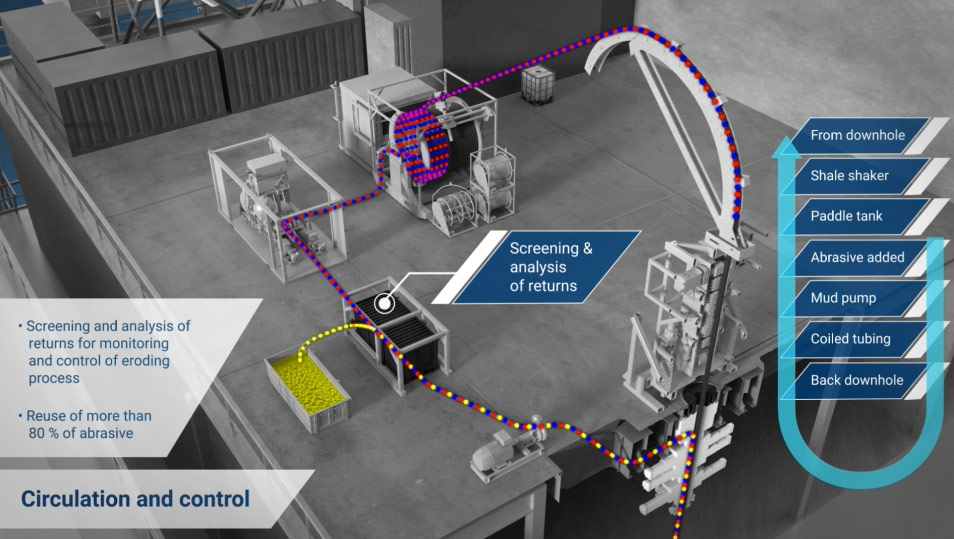

High efficiency in rigless plug and abandonment as well as production enhancement is ensured by ANT’s erosion tool wellANT which is based on the Water Abrasive Suspension (WAS) erosion technology.

Sie sehen gerade einen Platzhalterinhalt von YouTube. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenFields of application

- Erosion of restrictions and collapsed wells

- Swarfless section eroding for abandonment plugs

- Erosion for side tracking

Key Features

- Rigless solution

- Deployed on standard coiled tubing

- Small/micro cuttings

- Screening and analysis of returns

- Monitoring and control of eroding process

- Reuse of more than 80 % of abrasive

Your Advantages

- Control and feedback

- High flexibility

- Time savings

- Cost reduction

- Maximum safety

Collapsed and restricted wells

Restricted well access due to stuck objects, solids deposition or pipe deformations can cause extended non-productive times of associated assets as well as premature abandonment and challenging plugging.

Traditional pipe conveyed mechanical mills can suffer from unintended side tracking due to reactive torque from the deformation, and require expensive rig mobilisations.

In contrast, wellANT can be deployed on standard coiled tubing even from a Riserless Light Well Intervention (RLWI) vessel. A refined jet orientation ensures that the wellANT only erodes within the diameter of the existing wellbore, with very low reactive torque.

Section eroding

wellANT is also capable of 360-degree swarfless section eroding, which provides a fast and cost effective alternative to section milling.

As the tool erodes casing and concrete together, its consistent water jets will also erode through any other obstructions encountered, perfectly preparing a window for rock-to-rock T plugs.

Side tracking

Blog

Wissenschaftlich bestätigt: Wasserstrahltechnik als Schlüssel für sicheres und sauberes Schiffsrecycling

Eine wissenschaftliche Studie zeigt: Wasserstrahlschneiden reduziert Emissionen und Risiken beim Rückbau von Schiffen deutlich. Erfahren Sie, wie mobile Schneidsysteme wie WAS-Technologien die Lösung sein können.

Head of Engineering- Interview mit Eibe Dahl

Einblick ins Engineering: Eibe Dahl über Innovation, Strukturwandel und warum er sich bei ANT als Teil eines starken Teams angekommen fühlt.

Erfolgreiches 6. WAS-Training in Belgien: Positive Eindrücke und Erfahrungen mit MACE-Equipment

Anfang April kamen EOD-Teams für das internationale Wasser Abrasiv Suspension (WAS) Training in Belgien zusammen, initiiert von der belgischen EOD-Gruppe.

Any questions?

Our Sales Team is always happy to help. You can reach us by phone from Monday to Friday between 8 am and 4 pm.