Successful Application of Water Jet in Puncturing Gas Cylinders for Pressure Relief

In February 2024, Alexander Dölger and Manfred Hagenbrink conducted an impressive demonstration of ANT’s water jet suspension technology, showcasing the effectiveness and versatility of our products. The event took place at the training ground of a renowned firefighting facility, aiming to showcase the functionality and performance of miniMACE, the camera system, and the 2-axis cutting table.

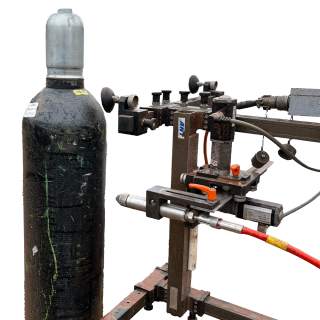

On the recommendation of a third party, the firefighting unit approached us seeking a reliable solution for safely relieving pressure from gas cylinders. Previous attempts using drilling methods proved ineffective due to the excessive force exerted by the drill, leading to either the cylinder slipping or tipping over, rendering the approach impractical and unsafe.

The demonstration involved puncturing gas cylinders in various scenarios:

Puncturing an empty gas cylinder: Our water-abrasive mixture enables rapid penetration of the steel shell within seconds. The generated pressure force is less than 35 Newtons, ensuring the stability of the gas cylinder.

Puncturing a partially filled gas cylinder: With the miniMACE system, we safely penetrate the wall and allow controlled release of the remaining gas—all from a safe distance.

Positive feedback from the firefighting unit and successful tests confirmed the effectiveness and practicality of our products in neutralizing gas pressure vessels.

The successful demonstration opens up new application possibilities for our company in the field of professional firefighting units, hazardous materials response teams, and technical rescue organizations.

Would you like more information or are you interested in a demonstration? Please leave your contact details.

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information