Energy production from offshore plants

They are located both inland and off the coasts of the country and help ensure that we don’t sit at home in the dark in the evenings or that our homes are toasty warm even when temperatures drop below zero in winter: offshore facilities such as oil platforms or drilling rigs and wind farms. Oil platforms enable the development of crude oil at depths of up to 3000 meters. Around one third of the world’s oil volume is developed through this so-called offshore extraction. In 2020, for example, more than 250 offshore oil and gas rigs were in operation.

Decommissioning of offshore installations

However, over the years, the wind and salt water take their toll on the turbines and offshore assets, causing damage to the structure of drilling rigs and thus impairing their use. The service life of some offshore facilities in the oil and gas industry is estimated at 20 to a maximum of 25 years – depending on the quality of maintenance and care. This means that not only the maintenance of offshore plants and structures is currently an important topic, but also the safe dismantling of these plants will become increasingly important in the coming years. A dismantling that is associated with special challenges due to the location of the offshore structures – directly in the water and thus completely surrounded by water. Specialists with experience and know-how are therefore in demand. As the global technology leader for mobile waterjet cutting, ANT AG stands for reliable, user-oriented and efficient technology. We know the special requirements that offshore structures in the oil and gas industry as well as in the wind industry pose at various stages of life cycle management. Our teams are ready with the right equipment to meet customers’ specific needs. Whether temporary or permanent decommissioning, maintenance, or efficient dismantling, we are the strong partner at your side.

Our waterjet technology for the offshore sector

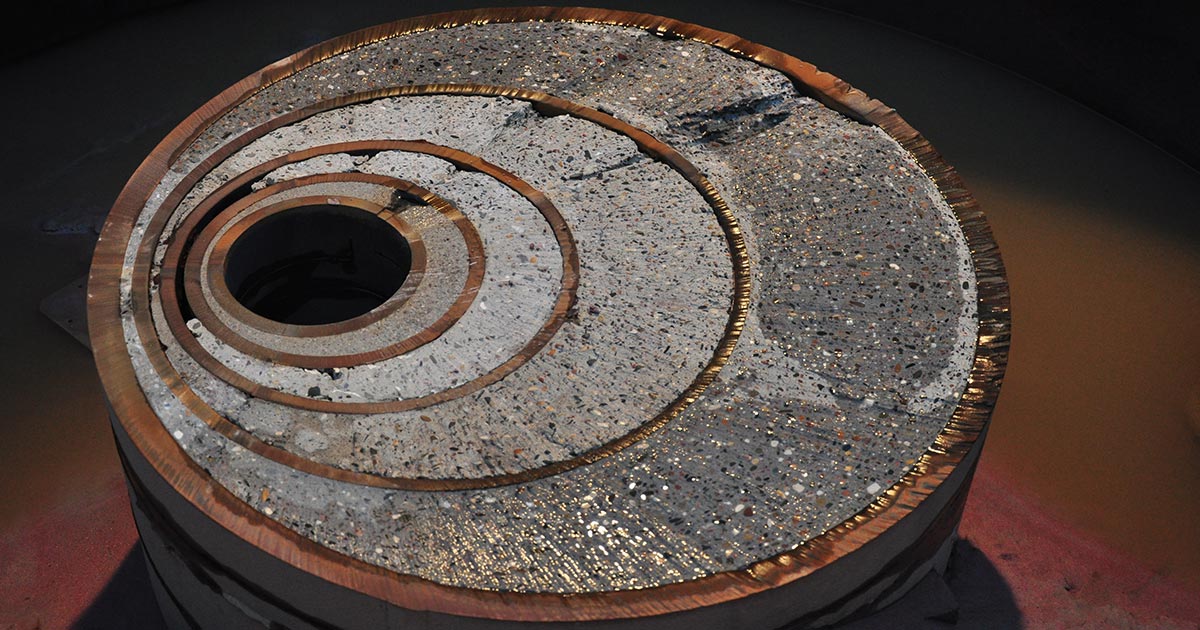

The fundamentals of our cutting technology are that the abrasive material is kept in suspension in a liquid (WAS) and conveyed to the cutting head, which has a nozzle with a smaller orifice than the conveying line, increasing the system pressure. This increased system pressure in turn leads to an increase in the velocity of the jet as it exits the nozzle. In the field of offshore structures, our cutting equipment is mainly used for

- multi string casing / conductor cutting below mudline

- subsea wellhead removal

- pile cutting

- subsea infrastructure cutting

- jacket and topside decom

Our technology has evolved over the years, has been tested and refined by our engineers in permanent development, and thus today meets the latest and most innovative standards. In cooperation with our in-house technology and the knowledge and know-how gained from over 20 years of market experience, it can be tailored to a wide range of scenarios and customer requirements. In addition, our technology is the only system in the world to feature verification software. This software transmits important data directly from the cutting device to operators live during the cutting process. A variety of special sensors on the unit send information via a cable to the operator’s panel. The computer software is then designed to read the data in an easy-to-understand manner – serving as a visual aid to the operator on the success of the cutting performance. This saves time – because tedious tests and repeated checks of the cutting job are eliminated.

We develop the most suitable strategies for our customers based on the following points in order to achieve the greatest possible efficiency in cutting:

- environment

- materials

- stresses and strains

- internal cavities / materials

- external visits

- location

- medium to be used

- access

Our vision: Our equipment should not only provide customers with maximum value and efficiency while reducing costs, but also leave as small an environmental footprint as possible in the process.

Did you already know?

Facts and figures

- The clear market leader in offshore wind farms is the UK. A total of 6 of the 20 largest offshore wind farms worldwide are located in British waters.

- At the end of 2021, there were around 1,500 offshore wind turbines connected to the grid in Germany. By comparison, at the same time there were almost 30,000 onshore wind turbines, around 20 times more onshore than offshore.

- In Germany, around 2,000 new wind turbines would have to be installed and commissioned by 2030 in order to achieve the targeted climate goals.

- Since 2017, the Wind Energy at Sea Act, or WindSeeG, has provided the legal framework for the installation of new offshore wind farms in Germany.

- Denmark was a pioneer in the field of offshore wind energy, as it was in the expansion of onshore wind energy. As early as 1991, the first wind farm consisting of a total of 11 turbines was connected to the grid near Vindeby. After Denmark, the Netherlands was the second country to drive the expansion and use of offshore wind energy.

- The number of drilling rigs in operation worldwide has fluctuated greatly over the past 40 years – and the trend is downward.

- Drilling rigs are largely made of steel and concrete and provide numerous tons of recyclable raw materials when they are disposed of.

- Drilling platforms often also serve as weather stations, whose readings can make an important contribution to the analysis of weather data over the oceans.

- The world’s largest production platform is the Norwegian Sea Troll, which measures a total height of 427 meters.

Our solutions for the offshore installations:

Internal cutting:

We offer our customers turnkey offshore cutting spreads, modular cutting tools and accessories for cold cutting of subsea and surface structures. In the field of internal cutting, we have developed special solutions to further improve the performance of downhole cutting heads (DCHs) at great depths and in difficult conditions for internal cuts. Even concentric multi-string dual bore wells can be completely cut in a single pass. Our integrated systems are thereby specifically and individually tailored to your needs.External cutting:

In the field of external cutting, we offer special manipulation systems for external cutting of oversized piles and other offshore structures that may not allow internal access. Our external cutting solutions complement our internal cutting equipment and cover a wide range of cutting tasks onshore and offshore.

wellANT

With wellANT we have developed an erosion tool specifically for rigless P&A and Production Enhancement. Would you like to learn more about our technology and the areas of application of our erosion tool? Then read our blog post about wellANT.

What makes us as a company

Are you looking for innovative solutions and the latest technology in waterjet cutting? Then benefit from our know-how and contact us. Rely on the technology leader and discover the new generation of waterjet cutting. Together we will take you into the modern future of cutting with our Water Abrasive Suspension (WAS) technology.

From abrasive mixing units (AMU), pumps, hydraulic power units and compressors to complete cutting guidance systems: With us, you get all components for the offshore sector from a single source, installed in containers or special frames for immediate use on site. Our equipment is state of the art. With us, you receive only the most innovative and powerful technology for your offshore solution – and on request as a complete system.

wellANT: further applications

New challenges and permanent development make our equipment always prior art. There are numerous problems for which our technology is interesting:

- topside cutting and inspections

- subsea inspections

- castellations

- marine growth removal

- pipeline and subsea infrastructure removal

- suction anchors

- renewables

- mono piles

- mooring chains

Discover our product portfolio for more sustainability

Would you like to learn more about how we ensure greater safety, sustainability and climate neutrality with our technology? Our sales team will be happy to answer all your questions.