Die effizienteste Art des Wasserstrahlschneidens

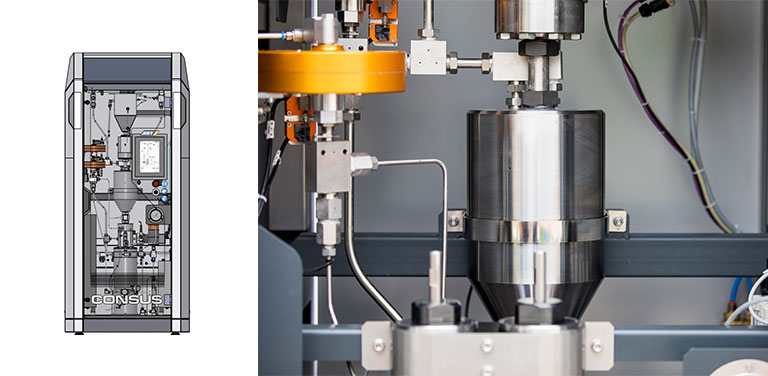

ConSus lock system

Stationary WAS cutting with Continuous Suspension (ConSus)

A worldwide patented lock system enables a continuous supply of the abrasive into the high-pressure vessel, thus ensuring an uninterrupted cutting in the Water Abrasive Suspension (WAS) cutting process.

How does waterjet cutting with the ConSus lock system work?

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationFields of application

- Processing industry

- Contract manufacturing

- Industrial cutting and slicing of high-strength, brittle or thick materials, composites and hollow sandwich structures

Advantages over the WAIS system*

- Only 1500 bar

- up to 3 times faster

- Kalter Schnitt

- 70% energy savings

- 70% less noise

- 50% less particle emissions

- 50% CO2 savings

- 50% cost savings

*Water Abrasive Injection System (WAIS) is the commonly used process in industrial manufacturing to date

Continuous Suspension (ConSus) briefly explained

The abrasive is filled from a hopper via a ball valve into an intermediate pressure vessel. From there it passes under pressure through another ball valve into the high-pressure vessel. Subsequently, the suspension is fed to the main water jet via the bypass valve and then to the nozzle.

Experts for stationary cutting with ConSus

This process is mainly used in the processing industry as well as in contract manufacturing. ConSus – ANT Stationary Cutting Solutions GmbH, as part of the ANT Group, is specifically dedicated to the requirements in this sector. therefore, you can obtain further information on the website www.consus-gmbh.com.

Do you have any questions?

Our project team will be happy to help. You can reach us by phone Monday to Friday from 8am to 4.30pm

Blog

ANT AG joins EMDAD at ADIPEC 2025

EMDAD as exhibitor at ADIPEC 2025—and ANT AG will join as a co-exhibitor. At our booth, ANT AG will focus on wellANT: the next-generation erosion tool based on Water Abrasive Suspension (WAS) technology.

DEMIL & Bomb Disposal – Three Opportunities for a Good Conversation

NATO EOD Bratislava (Booth 305), Milipol Paris (Hall 5A, M160 – co-exhibitor SCOPEX), and MILENG COE Ingolstadt (Booth 82). Book a meeting now: mace@ant-ag.com

Interview with Jennifer-Eileen TopkeHead of Inside Sales & Projects at ANT AG

Start your career at ANT AG! Find out how Jennifer-Eileen Topke went from sales assistant to head of inside sales and project management. Join our project management team and help shape exciting customer projects. Apply now: https://ant-ag.com/projektmanager-kundenprojekte